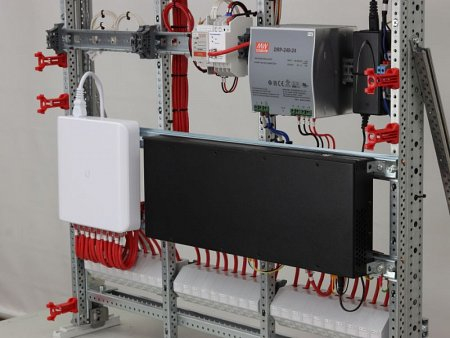

The special feature of a rail power supply is its type of mounting, to which it owes the name. In this accessory the power supply is attached to the standard-measure DIN rail, also known under the name hat rail.

How does a rail power supply work?

As previously mentioned, a rail power supply is a switched mode power supply. It converts a nonstabilised input voltage into a regulated output voltage. The conversion of an input ac to a higher-frequency supply is done by the rectifier and inverter electronics. A rail power supply then quickly switches power between the load and onboard inductors, as well as capacitors. The voltage conversion is achieved via transformer and, due to the involvement of high frequencies, it can be rather compact.

The advantages of a rail power supply

There are various advantages of a rail power supply. The most notable are: compactness, efficiency, ease of use, reliability, and versatility.

- Compactness

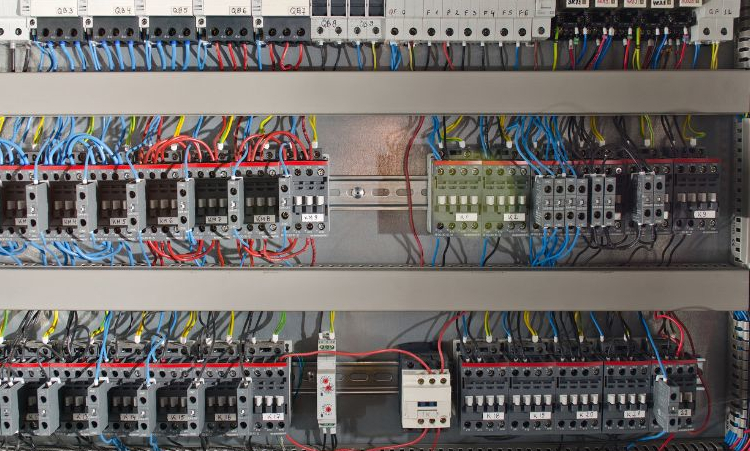

A rail power supply is typically very small. It is also way lighter and more compact than linear power supplies. All of these characteristics make it possible to install the device in tight spaces, such as electrical cabinets and control panels.

- Efficiency

A rail power supply is highly efficient – far more efficient than its unregulated and linear counterpart – reaching as much as 90% efficiency, which is further elevated by the minimal consumption of power under off-load conditions.

- Ease of use

The power supply built for rail mounting is very easy to install and operate. To securely attach the device, the use of the few or no tools is needed. The installation can be done manually, since most rail power supply units feature spring clamps, clips, or push-in terminals. Additionally, they are compatible with ring terminals, connectors, and stripped wires.

- Reliability

Another advantage of a rail power supply is its reliability. Most units of this sort contain no mechanical parts, which significantly reduces both the risk of failure, and the need for maintenance operations. Moreover, rail power supplies are usually equipped with safety circuits, which allows to protect the internal subcomponents, together with the connected industrial components.

- Versatility

Rail power supplies are very versatile. They come with various functions and specifications, which allow them to suit every need of the user. Among the most notable are universal AC single phase input voltage, wide selection of DC output voltages, as well as wide selection of power ratings. Additionally, the rail power supplies offer almost unlimited selection of available electrical components, namely power supplies, circuit breakers, relays, and industrial PCs.

The disadvantages of a rail power supply

Aside from numerous advantages, a rail power supply has also some disadvantages. The user needs to precisely define the settings of the device at the stage of designing busbars between transformers and switchboards, generators and switchboards, or between switchboards. Users of rail power supplies also need to thoroughly select the components of busbars before their production, having in mind they cannot be modified in any way. Another disadvantage of a rail power supply is connected to the fact a failure of one element in a busbar line can lead to a power failure in all receivers attached to the line.

The applications of a rail power supply

Rail power supply is found in most industrial applications all around the world. It is one of the key components of cabinets, distribution boxes, and machines. Rail power supplies are used in mechanical engineering, industrial automation, automotive industry, process industry, logistics, and wind power among others. The most common applications of this type of device are sensors, security and alarms, transmitters and receivers, solenoids and actuators, as well as motors and relays.